A free communication space for Neuro-Symbolic AI lovers.

A new collaborative innovation paradigm of industry, academy, research and education.

A new mechanism of technology innovation, application demonstration and industry incubation for the transformation of achievements.

Our value: innovation, inclusion, sustainability, openness and community

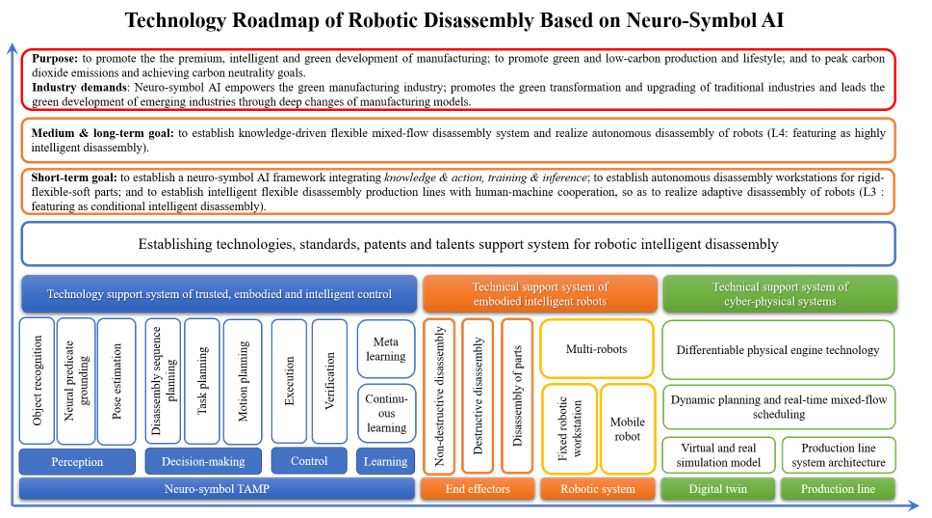

AI empowers the green manufacturing industry: by promoting the green transformation and upgrading of traditional industries through profound changes in manufacturing models. It also promotes the premium, intelligent, and green development of manufacturing, green and low-carbon production and lifestyle, and aims to peak carbon dioxide emissions and achieve carbon neutrality goals.

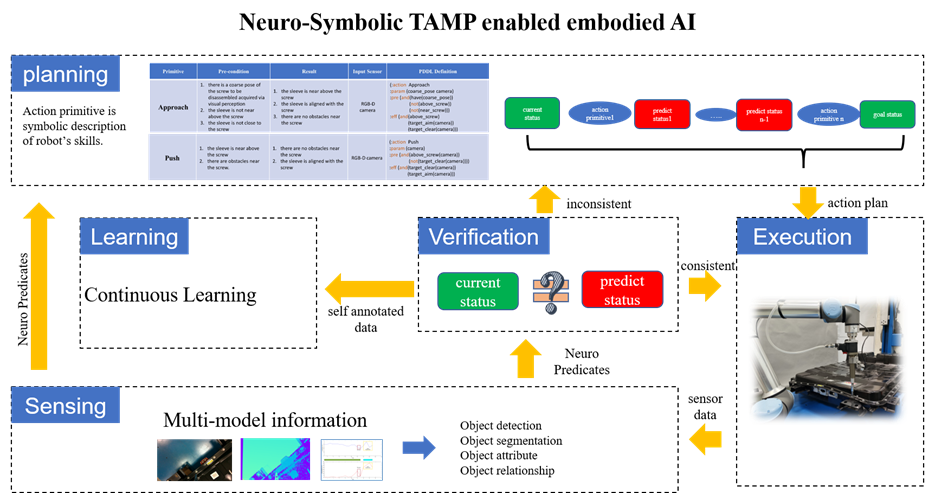

Developing a robotic embodied intelligent control architecture that integrates knowledge & action, training & inference, and a safe and controllable intelligent dismantling technology system.

Developing autonomous disassembly robots based on Neuro-Symbolic AI, and establishing knowledge-based flexible disassembly production system to achieve intelligent disassembly of multiple varieties & small batches of end-of life products in complex and dynamic scenarios.

- June 19, 2023, the 1st Neuro-Symbolic AI HOME Summer School was held online. (PDF)

- July 10-12, 2023, Ningbo China, a workshop on the Technology Roadmap of Robotic Disassembly Based on Neuro-Symbolic AI was held. (PDF)

- June 24-25, 2024, Shanghai Jiao Tong University, a workshop on the 2024 Neuro-Symbolic AI HOME was held. (PDF)

- June 25-July 11, 2024, Shanghai Jiao Tong University, the 2024 Neuro-Symbolic AI HOME Summer School was held. (PDF)

- September, 2024, the Technology Roadmap 2.0 of Robotic Disassembly Based on Neuro-Symbolic AI was released. (PDF)

- September, 2025, the Technology Roadmap 3.0 of Robotic Disassembly Based on Neuro-Symbolic AI was released. (PDF)

- January, 2026, the Position Paper of the Neuro-Symbolic Ai Home—On the Cybernetics Stance of Neuro-Symbolic Embodied Intelligence Systems was released. (PDF)

Development history

- April 16, 2025, Mr. Peng Yanlong was honored with the "Dream Building Scholarship" in recognition of his outstanding contributions to the field of innovative autonomous remanufacturing of power batteries, enabled by neural symbolic embodied intelligence. (PDF)

- August 16, 2025, Neural-Symbolic empowering Green ManufacturingTeam Wins Grand Prize at the 2025 Intel AI Innovation Application Contest. (PDF)

- August 17–21, 2025, Los Angeles, The RobKiNet, a kinematics-informed neural network was proposed. (PDF)

- August 17–21, 2025, Los Angeles, A continual learning framework based on NeuroSymbolic task and motion planning (TAMP) was proposed. (PDF)

Exciting Moment

- Technology Roadmap of Robotic Disassembly Based on Neuro-Symbolic AI (Ver. 2023) (PDF)

- Technology Roadmap 2.0 of Robotic Disassembly Based on Neuro-Symbolic AI (Ver. 2024) (PDF)

- Technology Roadmap 3.0 of Robotic Disassembly Based on Neuro-Symbolic AI (Ver. 2025) (PDF)

Technology Roadmap

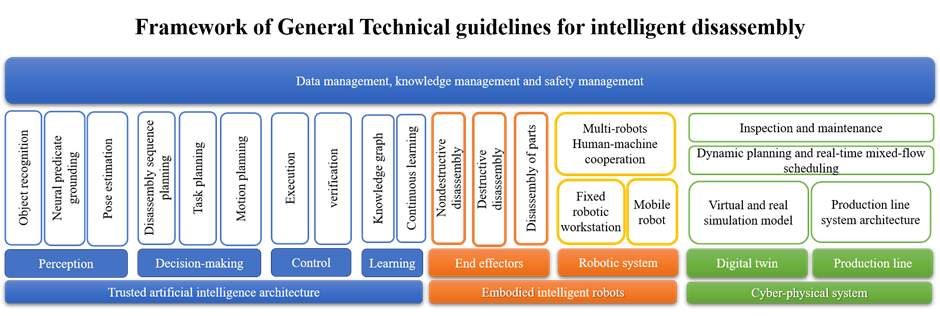

- Standardize the technical requirements for multimodal information perception, autonomous decision-making control, human-machine collaborative systems, dynamic planning, real-time scheduling, detection and maintenance, data knowledge management, security management, and other aspects in intelligent dismantling. (PDF)

Standardization of AI in Green Manufacturing

General Technical guidelines for intelligent disassembly

- Special design for young students who are passionate about Neuro-Symbolic AI, and aspire to further their studies in the field of intelligent robotics.

- Deeply understanding the principles and technologies of Neuro-Symbolic AI, cognitive robots, machine learning.

- Improving comprehensive abilities in scientific research, and cultivating critical AI thinking.

- The 1st Neuro-Symbolic AI HOME Summer School (June 19, 2023, online) (PDF)

- 2024 Neuro-Symbolic AI HOME Summer School - Course Schedule (PDF)

- Neural Symbolic AI Summer School: Knowledge You Should Have Before Starting (PDF)

- The 2024 Neuro-Symbolic AI HOME Summer School triumphantly concluded! (PDF)

- The Syllabus for 2025 Neuro-symbolic AI Home Summer School has been officially released! (PDF)

Summer school

Experience learning in a way you have ever had!

- Autonomous disassembly robot for EV batteries based on Neuro-Symbolic AI

(PDF)

- Accurate screw detection method for autonomous robotic disassembly of EV batteries

(PDF)

- Robust screw head fitting method for robotic disassembly of EV batteries based on force perception

(PDF)

- Autonomous decision and planning method based on symbolic operators

(PDF)

- Intelligent tasks planning for robotic disassembly of EV batteries based on large language models

(PDF)

- Multifunctional autonomous dismantling workstation for screws of EV batteries

(PDF)

- Digital twin of autonomous disassembly robots for spent traction batteries

(PDF)

Inclusive projects

- Neuro-Symbolic Task and Motion Planner for Disassembly Electric Vehicle Batteries[J]. Journal of Computer Research and Development, 2021, 58(12): 2604-2617. (in Chinese) (PDF)

- A Method of Domain Dictionary Construction for Electric Vehicles Disassembly[J]. Entropy 2022, 24(3), 363. (PDF)

- A novel knowledge-driven flexible human-robot hybrid disassembly line and its key technologies for electric vehicle batteries[J]. Journal of Manufacturing Systems 68 (2023) 338-353. (PDF)

- An accurate activate screw detection method for automatic electric vehicle battery disassembly[J]. Batteries, 2023, 9(3),187. (PDF)

- Deliberating on Intelligent Robotic Disassembly of End-of Life EV Batteries [J]. Automobile & Parts, 2023(05):54-58. (in Chinese) (PDF)

- Towards Agile Robots: Intuitive Robot Position Speculation with Neural Networks[J]. arXiv preprint arXiv:2402.16281, 2024. (PDF)

- Experience-Driven NeuroSymbolic System for Efficient Robotic Bolt Disassembly[J]. Batteries, 2025, 11(9): 332. (PDF)

Journal Articles

- Decoding RobKiNet: Insights into Efficient Training of Robotic Kinematics Informed Neural Network[C]//2025 IEEE 21st International Conference on Automation Science and Engineering (CASE). IEEE, 2025: 1547-1554. (PDF)

- Embodied Intelligence in Disassembly: Multimodal Perception Cross-valiation and Continual Learning in Neuro-Symbolic TAMP[C]//2025 IEEE 21st International Conference on Automation Science and Engineering (CASE). IEEE, 2025: 1561-1568. (PDF)

- Revolutionizing Battery Disassembly: The Design and Implementation of a Battery Disassembly Autonomous Mobile Manipulator Robot(BEAM-1).2024 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS). IEEE, 2024: 6367-6374. (PDF)

- Robotic Autonomous Disassembly System for Automotive Power Battery Remanufacturing[C]//International Workshop on Autonomous Remanufacturing. Cham: Springer Nature Switzerland, 2024: 71-83. (PDF)

- Autonomous Electric Vehicle Battery Disassembly Based on NeuroSymbolic Computing[C]//Proceedings of SAI Intelligent Systems Conference. Springer, Cham, 2023: 443-457. (PDF)

- Development of an Autonomous, Explainable, Robust Robotic System for Electric Vehicle Battery Disassembly[C]//2023 IEEE/ASME International Conference on Advanced Intelligent Mechatronics (AIM). IEEE, 2023: 409-414. (PDF)

- Design and Implementation of a Multifunctional Screw Disassembly Workstation[C]//International Conference on Intelligent Robotics and Applications. Singapore: Springer Nature Singapore, 2023: 506-519. (PDF)

- Boosting Robot Intelligence in Practice: Enhancing Robot Task Planning with Large Language Models[C]//2023 8th International Conference on Robotics and Automation Engineering (ICRAE). Singapore: Singapore, 2023: 90-94. (PDF)

- A SWOT and AHP Methodology for the formulation of development strategies for Chinas waste EV battery recycling industry[C]//Cascade Use in Technologies 2018: Internationale Konferenz zur Kaskadennutzung und Kreislaufwirtschaft–Oldenburg 2018. Berlin, Heidelberg: Springer Berlin Heidelberg, 2018: 83-92. (PDF)

Conference Papers

- Position Paper of the Neuro-Symbolic Ai Home—On the Cybernetics Stance of Neuro-Symbolic Embodied Intelligence Systems (PDF)

- Technology Roadmap 3.0 of Robotic Disassembly Based on Neuro-Symbolic AI (Ver. 2025) (PDF)

- Technology Roadmap 2.0 of Robotic Disassembly Based on Neuro-Symbolic AI (Ver. 2024) (PDF)

- Technology Roadmap of Robotic Disassembly Based on Neuro-Symbolic AI (Ver. 2023) (PDF)

- Neural-Symbolic Embodied Intelligence: Innovative Practices for Empowering Green Manufacturing (The 3rd Academic Conference on Human-Centered Smart Manufacturing, Beijing) (PDF)

- Green, Low-Carbon, Circular, Intelligent: The New Pathway for Productivity Growth in the Automotive Industry(An Introduction to NIO's Blue Book on Vehicle Circularity) (PDF)

- Summary Report: The 2024 Neuro-Symbolic AI HOME Summer School at Shanghai Jiao Tong University (PDF)

- CNCC 2024 Technical Forum Invited Pesentaion: NeuroSymbolic TAMP-Innovative Practices Driving the Embodiment of Industrial Robots (PDF)

- Lecture 1 on Neuro-Symbolic AI - Neuro-Symbolic AI and Its Key Technologies (PDF)

- Lecture 2 on Neuro-Symbolic AI - Principles and Implementation of Robot Position Speculation Networks (PDF)

- Lecture 3 on Neuro-Symbolic AI - A Spent Traction Battery Dismantling System with Autonomous Explainability and Robustness (PDF)

- Lecture 4 on Neuro-Symbolic AI - Autonomous Dismantling of Various Types of Fasteners Based on Neuro-Symbolic AI (PDF)

- Lecture 5 on Neuro-Symbolic AI - Enhancing Robot Task Planning with Large Language Models (PDF)

- Lecture 6 on Neuro-Symbolic AI - Robot Planning and Practice in Complex Environments (PDF)

- Lecture 7 on Neuro-Sicymbol AI - A Knowledge-Driven Man-Machine Mixed-Flow Dismantling Production Line for Spent Traction Batteries (PDF)

- Lecture 8 on Neuro-Symbolic AI - Research on Electrostatic Separation Product Recognition Methods for Automotive Polymers Based on Neuro-Symbolic AI (PDF)

- Lecture 9 on Neuro-Symbolic AI - Fundamental Research Progress and Scientific Issues in Neuro-Symbolic AI Since 2020 (PDF)

- Lecture 10 on Neuro-Symbolic AI - The Evolution and Development of Robot Control Technology (PDF)

- Lecture 11 on Neuro-Symbolic AI- Neural-Symbolic Advances in Embodied AI for Industrial Robots (PDF)

Special reports

- Autonomous disassembly robot for EV batteries based on Neuro-Symbolic AI (2022 video)

- Multifunctional autonomous dismantling workstation for screws of EV batteries (2023 video)

- Digital Twin System for Robotic Disassembly Workstation(2024 video)

- Towards Agile Robots: Intuitive Robot Position Speculation with Neural Networks RPSN(2024 video)

- Digital twin of autonomous disassembly robots for spent traction batteries(2025 video)

- Specifications for dataset design, collection and annotation (PDF)

- Datasets and models of EV batteries for deep learning objects detection algorithms and positioning tasks.

- The EV batteries image dataset (Part 1) includes 1719 RGB images of EV batteries, and all screws in the images are manually labeled using LabelImg software. This dataset includes a total of 6992 external hex screws and 687 hex nuts.

- The EV batteries image dataset (Part 2) includes 1159 RGB images of EV batteries, including image information of each stage of EV battery disassembly, for the identification and testing of various modules of EV batteries.

- The EV batteries image dataset (Part 3) includes 1200 RGB images of EV batteries. All screws in the images are manually labeled using LabelImg software and classified based on the current disassembly state (whether the end effector is aligned, whether there are obstacles, etc.) for training neural predicate models.

- The EV batteries image dataset (Part 4) includes 300 RGB images of common screws in EV batteries, and all screws in the images are manually labeled using LabelImg software. This dataset includes eight types of screws with different specifications, including external hexagonal screws, internal hexagonal screws, cross screws, and star screws.

- Specifications for Neuro-Symbolic AI HOME satellite laboratory certification and accreditation (PDF)

- Neuro-Symbolic Al HOME Satellite Laboratories

- Neuro-Symbolic AI HOME (Shanghai Caohejing) Satellite Laboratory (PDF)

- Neuro-Symbolic AI HOME (Shanghai Jiading) Satellite Laboratory (PDF)

- Neuro-Symbolic AI HOME (Shanghai Songjiang) Satellite Laboratory

- Neuro-Symbolic AI HOME (Shanghai Minhang) Satellite Laboratory (PDF)

- Neuro-Symbolic AI HOME (Wuhan Qingshan) Satellite Laboratory (PDF)

- Neuro-Symbolic AI HOME (Kunming University Town) Satellite Laboratory (PDF)